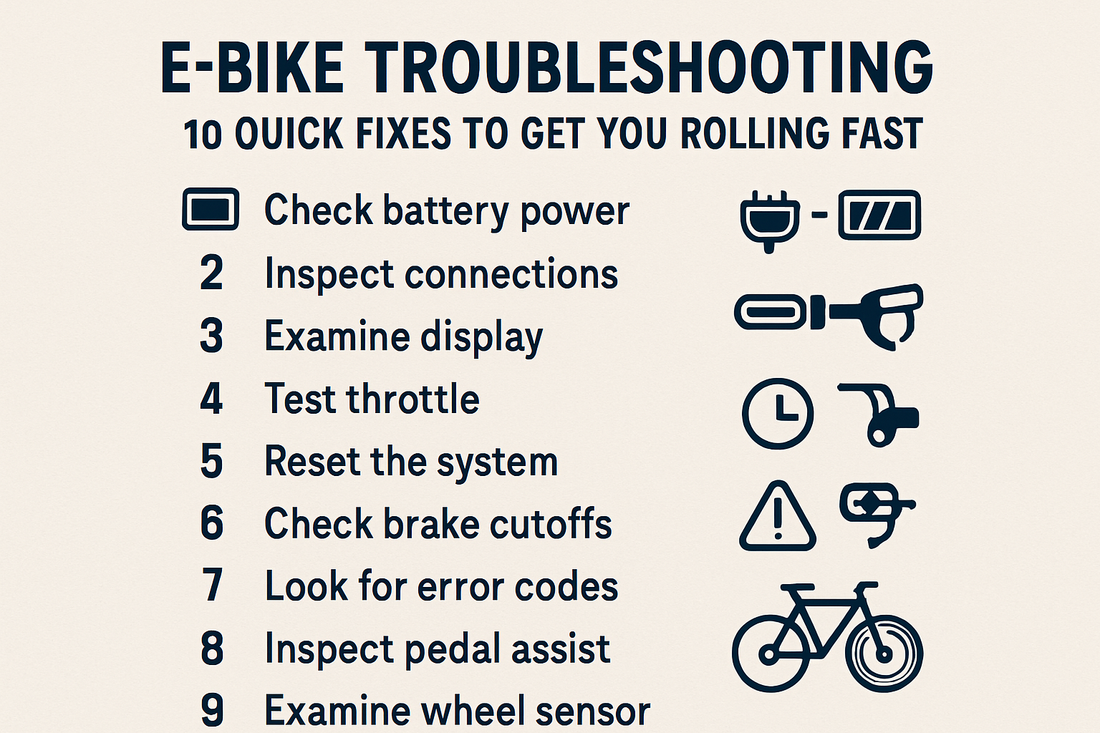

Ebike Troubleshooting: 10 Quick Fixes to Get You Rolling Fast

Share

Understanding Common E-bike Malfunctions

Electric bicycle complications frequently manifest during the most inconvenient moments—typically when you're rushing to an important meeting or navigating through congested urban thoroughfares. These sophisticated pedal-assist vehicles integrate complex electrical systems with traditional mechanical components, creating multiple potential failure points that can disrupt your sustainable commuting routine.

The intricate interplay between battery management systems, motor controllers, and drivetrain components means that even minor malfunctions can cascade into significant performance degradation. Understanding the fundamental architecture of your e-bike's electrical and mechanical systems empowers you to diagnose issues swiftly and implement effective remedial measures.

Essential Diagnostic Procedures

Before delving into specific remediation techniques, establishing a systematic diagnostic methodology proves crucial for efficient ebike troubleshoot scenarios. Professional technicians utilize a hierarchical approach that prioritizes the most probable culprits while minimizing unnecessary component manipulation.

Begin your assessment by examining the display console for error codes or anomalous readings. These alphanumeric indicators often provide direct insights into malfunctioning subsystems. Subsequently, verify all electrical connections remain secure and corrosion-free, as environmental exposure frequently compromises contact integrity in metropolitan environments.

Power System Solutions

Battery Optimization Techniques

Lithium-ion cell degradation represents the predominant power-related issue affecting urban e-bike performance. When experiencing insufficient range or sudden power cutoffs, initiate a complete discharge-recharge cycle to recalibrate the battery management system's state-of-charge calculations.

Temperature extremes significantly impact electrochemical performance. If your battery exhibits reduced capacity during winter months, allow the pack to reach ambient temperature before charging. Conversely, excessive heat exposure can trigger thermal protection protocols, temporarily disabling power output until cooling occurs.

Charging Infrastructure Problems

Defective charging equipment often masquerades as battery failure. Inspect your charging cable for physical damage, particularly near connection points where repeated flexing causes conductor breakage. Utilize a multimeter to verify output voltage matches manufacturer specifications before assuming battery degradation.

For professionals seeking reliable power solutions, the 1000W Electric Bike with Removable Battery offers exceptional versatility for troubleshooting scenarios. This robust platform features a detachable power pack that enables convenient indoor charging while maintaining your bike's security in urban parking environments. The removable design also facilitates rapid battery swapping, minimizing downtime when primary cells require maintenance or replacement.

Motor and Drivetrain Remediation

Sensor Calibration Methods

Pedal-assist systems rely on precise torque and cadence measurements to deliver seamless power assistance. When experiencing erratic motor engagement or delayed response, sensor recalibration often resolves these anomalies without requiring component replacement.

Access your bike's configuration menu through the display interface and locate the sensor calibration function. Follow the prescribed procedure, which typically involves pedaling at various cadences while the system records baseline measurements. This process reestablishes proper communication between the sensor array and motor controller.

Chain and Gear Optimization

Mechanical drivetrain issues frequently compound electrical problems, creating complex symptom patterns that obscure root causes. Examine your chain for excessive elongation using a chain checker tool—stretched chains cause poor shifting performance and accelerated sprocket wear.

Derailleur misalignment manifests as grinding noises and incomplete gear changes. Adjust the limit screws and cable tension to restore precise shifting characteristics. Remember that e-bikes generate higher torque loads than conventional bicycles, necessitating more frequent drivetrain maintenance intervals.

Vroom Bikez offers an extensive electric bikes collection featuring models engineered for urban durability and minimal maintenance requirements. These carefully curated e-bikes incorporate robust drivetrains and intuitive diagnostic systems that simplify troubleshooting procedures for busy professionals. Each model undergoes rigorous quality testing to ensure reliable performance in demanding metropolitan conditions.

Display and Control System Fixes

Malfunctioning display units disrupt your ability to monitor critical parameters and adjust assistance levels. When screens remain blank or exhibit corrupted information, systematic component isolation helps identify the problematic element.

Disconnect and reconnect all display connections, ensuring proper seating in their respective ports. Moisture ingress frequently causes intermittent failures, so inspect connector seals for damage or contamination. If problems persist, attempt a factory reset through the hidden service menu—consult your manufacturer's documentation for specific key combinations.

"Regular preventive maintenance prevents 80% of common e-bike failures, significantly reducing the likelihood of experiencing roadside breakdowns during critical commuting periods."

Brake System Maintenance

Regenerative braking systems require specialized attention beyond conventional brake maintenance protocols. These sophisticated mechanisms recover kinetic energy during deceleration but can malfunction when components drift out of specification.

Inspect brake lever sensors for proper gap adjustment—excessive clearance prevents regenerative mode activation, while insufficient spacing causes constant drag. Clean sensor surfaces with isopropyl alcohol to remove accumulated debris that interferes with magnetic field detection.

| Symptom | Probable Cause | Quick Fix |

|---|---|---|

| Reduced braking power | Contaminated brake pads | Clean with degreasing solution |

| Squealing noises | Glazed brake surface | Light sanding with fine grit |

| Spongy lever feel | Air in hydraulic system | Bleed brake lines |

Connectivity and Smart Feature Troubleshooting

Modern e-bikes integrate sophisticated connectivity features that enhance the riding experience but introduce additional complexity. Bluetooth pairing failures and mobile application synchronization issues frequently frustrate tech-savvy urban professionals.

Clear your device's Bluetooth cache and unpair all existing connections before attempting to reestablish communication. Ensure your smartphone's operating system remains current, as outdated firmware often creates compatibility conflicts with newer e-bike protocols.

Preventive Maintenance Protocols

Implementing structured maintenance schedules dramatically reduces the frequency of unexpected failures. Urban environments present unique challenges including road salt exposure, temperature fluctuations, and vibration from uneven pavement surfaces.

Establish weekly inspection routines that encompass:

- Tire pressure verification and tread condition assessment

- Brake pad wear measurement and rotor inspection

- Chain lubrication and tension adjustment

- Electrical connection integrity verification

- Battery charge cycle optimization

Professional servicing intervals should align with manufacturer recommendations while accounting for increased usage patterns typical of daily commuting scenarios. Document all maintenance activities to identify recurring issues and optimize component replacement schedules.

When to Seek Professional Assistance

While many ebike troubleshoot procedures fall within the capabilities of mechanically inclined riders, certain scenarios require specialized diagnostic equipment and technical expertise. High-voltage electrical systems present safety hazards that exceed typical DIY comfort zones.

Motor controller programming, battery cell balancing, and torque sensor calibration necessitate manufacturer-specific tools and training. Attempting these procedures without proper equipment risks component damage and potential safety hazards. Establish relationships with qualified service centers before experiencing critical failures to ensure rapid resolution when professional intervention becomes necessary.

Investing in quality diagnostic tools and developing systematic troubleshooting methodologies transforms frustrating breakdowns into manageable maintenance events. Your commitment to understanding these sophisticated machines ensures reliable, sustainable transportation that supports your urban professional lifestyle while contributing to environmental sustainability goals.